On Friday, June 16th, MAX joined the Georgia Manufacturing Alliance (GMA) to learn about one of Georgia’s larger employers – Alcon, a global leader in eye care and the largest eye care device company in the world. Alcon provides innovative products that enhance quality of life by helping people see better and much of this work is happening at the company’s Johns Creek production, R&D, and distribution facilities.

At its Johns Creek facilities, Alcon produces 5,000 pairs of contact lenses per minute. As MAX and GMA members learned from Alcon Johns Creek General Manager Shay Foley, it takes a combination of highly trained personnel, rather sophisticated, high-tech robotics, and a reliable, global supply chain to make this possible. The company’s Johns Creek manufacturing facilities includes several lines of production within pristine work conditions, conditions that every employee bears responsibility for upholding.

Educational requirements for positions at Alcon range from a high school diploma to a PhD, with significant on-the-job training provided for several positions. Employees represent a wide range of expertise. What position is most challenging to fill for Alcon? Electrical mechanics, says Foley.

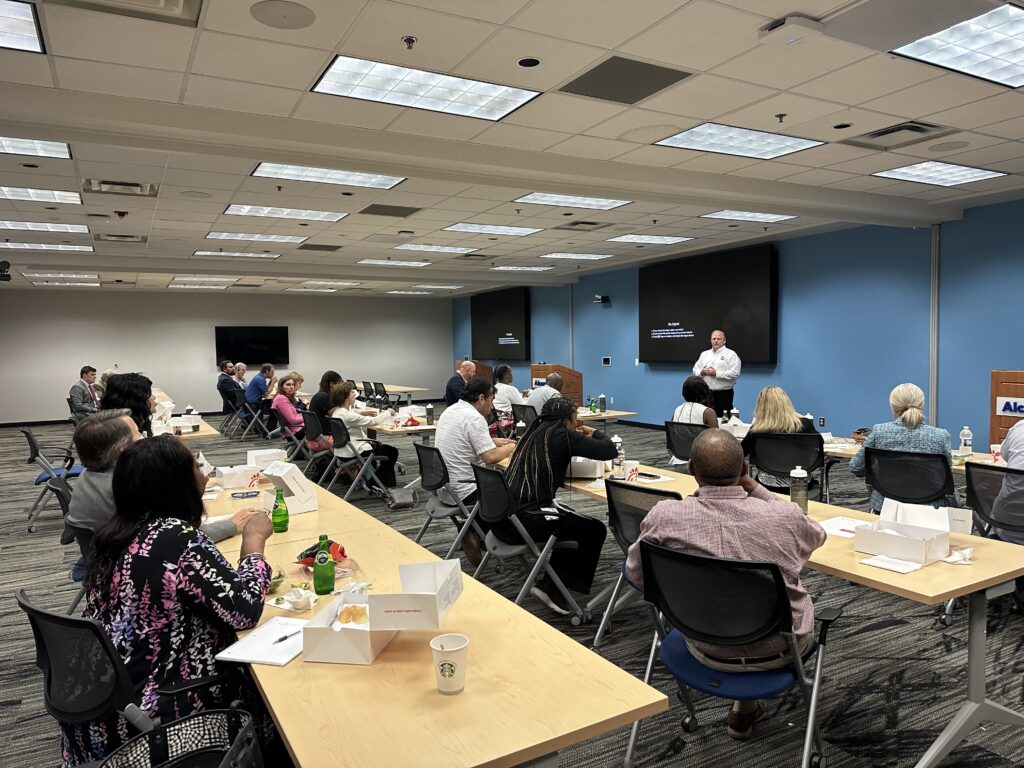

Two tour groups of MAX and GMA members were guided through the production facilities with Foley as their guide. The groups enjoyed a joint lunch-n-learn with Foley along with GMA President Jason Moss and MAX Board Member Joe Paolini, Vice President with the Bobby Dodd Institute (BDI).

Special thanks to Foley, Moss, and Paolini for their partnership in creating this special opportunity to learn about Alcon!

ABOUT MAX TALKS

Launched in 2014, the mission of MAX is to advance economic competitiveness in the Atlanta region by strengthening connections, collaborations, and practices among workforce developers and organizations engaged in workforce development.

Through the MAX Talks series, MAX seeks to provide opportunities for workforce developers to hear directly from employers about their current and emerging workforce needs.